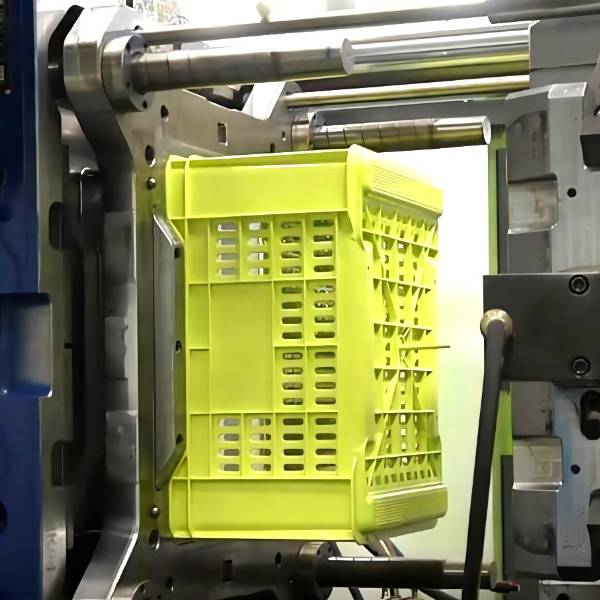

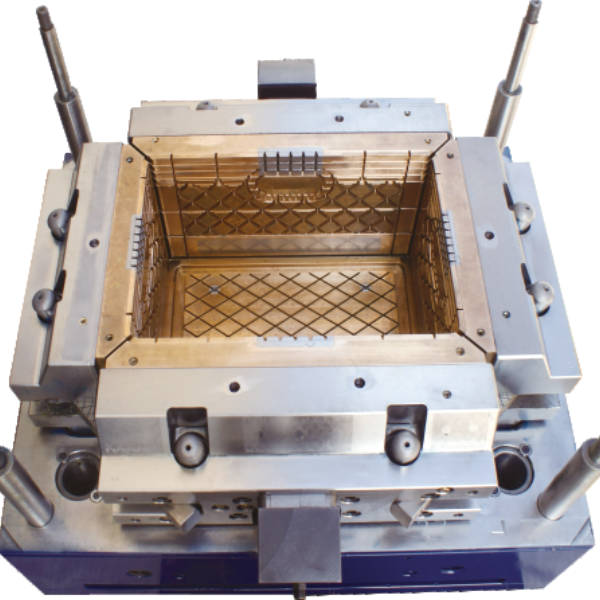

Fruit and Vegetable Crate Mold | Plastic Crate mold Manufacturer1

Focus on providing customer with various kinds of fruit and vegetable crate molds .

GEENO Mould offering various kinds of plastic crate moulds for you .

Annual export at least 120 stes crate moulds all over the world .

We not only provide customers with a high efficiency, high quality mold.

More focused on providing customers with the most professional technical support and advice,

so that customers spend the least money to receive the most valuable mold or equipment.

Inquiry Now

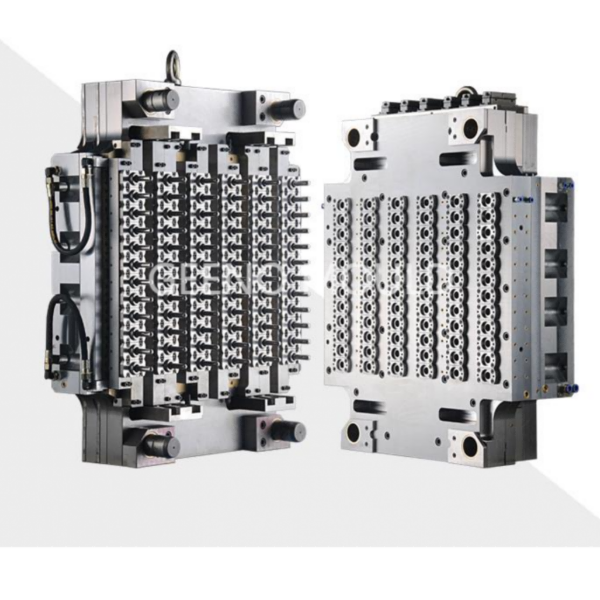

Specification

| Crate Dimension | 580X395X310mm |

| Crate Weight | 1650-1680g |

| Mould Core & Cav Steel | P20/718H |

| Delivery Time | 45-55 days |

| Mould Runner System | Direct gate |

| Mould Cycle Time | 40s |

Descriptions

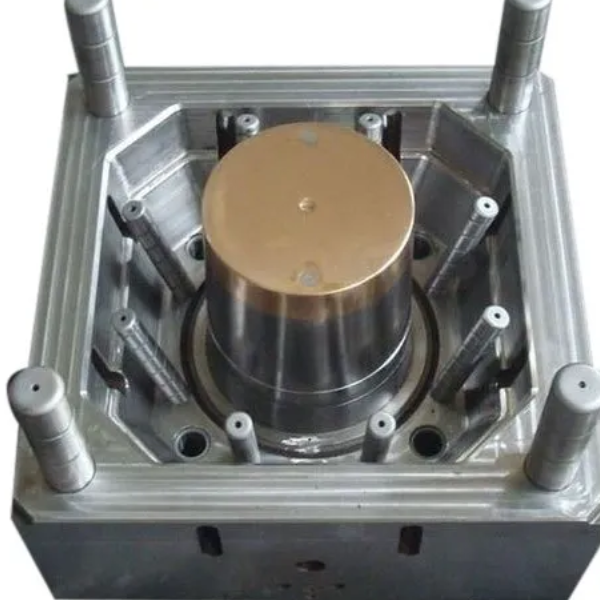

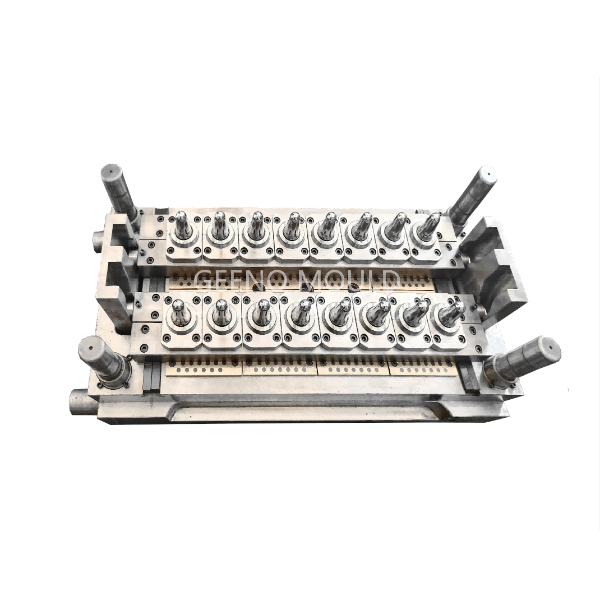

Welcome to GEENO Mould&Plastic Group ,which has more than 15 years experience for R&D,

making mould and offering Turnkey Solution for customers all over the world.

A turnkey injection moulding solution supplier in the hometown of Mold manufacturig in China - Taizhou Huangyan district .

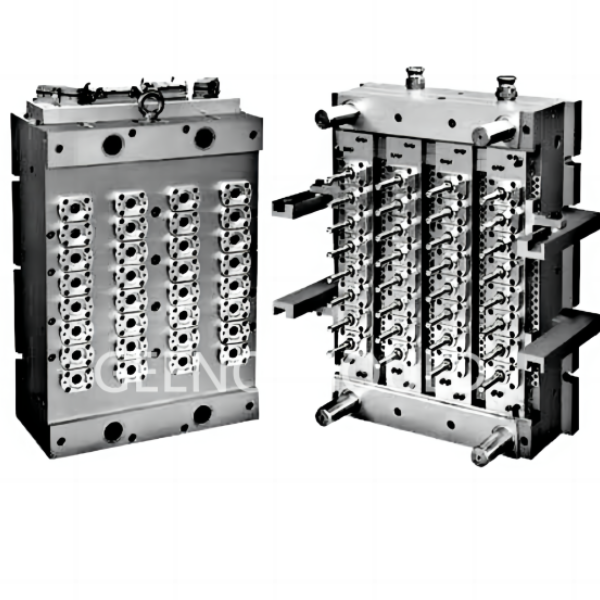

professional at mold design and research, mold manufacturing, and injection molding machine matching selection.

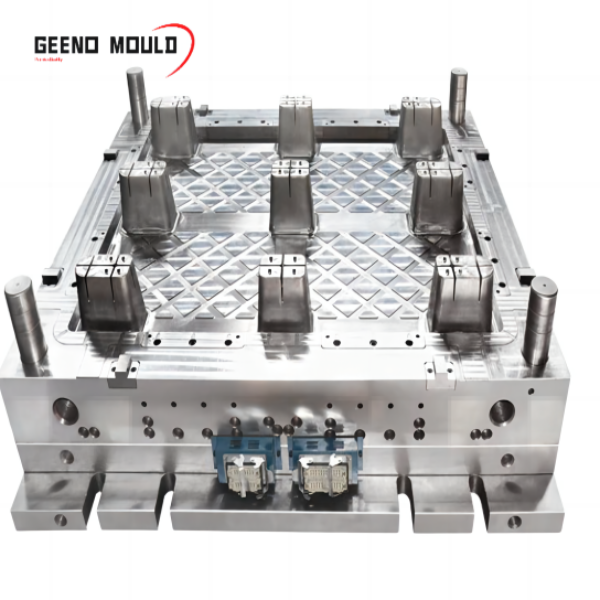

With Years of experienced in different Crate mould making , GEENO team pay more attention to check the crate weight and strength before design .

Optimize waterway design according to the actual situation of customer's plant to recommend suitable runner design and mould size.

Optimize mold dimension as much as possible to save cost for customers. But at the same time to ensure the life and quality of the mold,

to achieve 1+1>2 of the optimal scheme for customer.

Our Advantages :

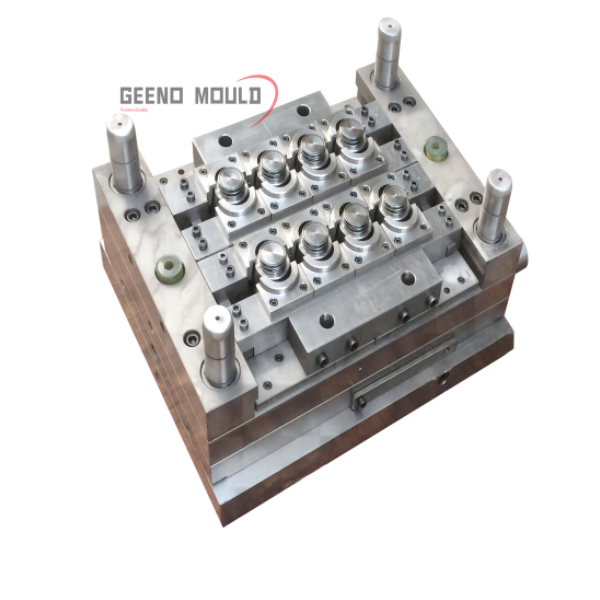

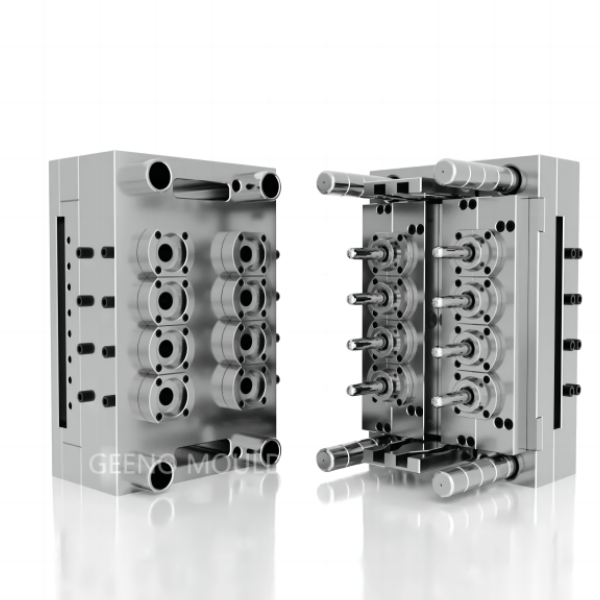

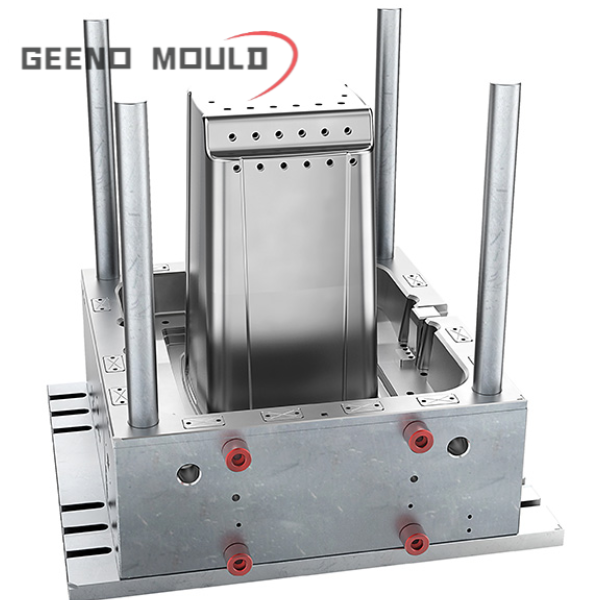

Geeno own rich project accumulation and precipitation and the strong professional customer team project communication,

So that our team has more comprehensive experience accumulation.

We not only provide customers with a high efficiency, high quality mold.

More focused on providing customers with the most professional technical support and advice,

so that customers spend the least money to receive the most valuable mold or equipment.

For example: the same turnover box product, we can meet the size and weight requirements of customers

based on professional mold flow analysis and design analysis. for customers to optimize the design and waterway layout.

To optimize the mold size, the 650T machine was originally needed, but after optimization by our team, only the 550T machine can be realized.

For customers to save energy consumption and space, but also reduce the cost.

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message