How To Choose Thin-wall Container Mould’s Steel ?

2023-09-11 | NEWS

How To Choose Thin-wall Container Mould’s Steel ?

The popularity of takeaway packaging has made the demand for disposable packaged lunch boxes great, and the market of packaging box mould has also caught up with the tide of development. The disposable lunch box has a low profit, so it needs to rely on the quantity to fight the market, which requires it to be high-speed and efficient in order to produce, and the lunch box mold needs to be produced with a high-speed machine, in the high-speed machine high-pressure, high-speed injection environment, the mold needs to withstand high pressure, so the manufacturing mold needs to use high hardness steel. Below, please follow the years of research and development and manufacturing experience of GEENO MOULD to briefly talk about how to choose the mold steel of the thin-wall lunch box?

The steel materials available for disposable lunch box molds are DIN1.2316, DIN1.2344, DIN1.2738, S136, H13 and other hard steels. The reason for choosing these hard steels is that they can prevent mold deformation under high pressure injection and prevent product defects such as flash edge. Among them, S136 stainless steel is the preferred recommendation for customers.

|

Type of steel material |

Steel material characteristics |

|

DIN1.2316 |

High hardness,High temperature resistance |

|

DIN1.2344 |

High temperature resistance, high toughness, and high plasticity |

|

DIN1.2738 |

Excellent polishing performance,Good machinability |

|

S136 |

Good polishing performance,Better transparency |

|

H13 |

Good wear resistance,High hardenability |

There are several reasons for recommending S136 stainless steel: On the one hand, stainless steel, food safety is more guaranteed. Secondly, the stainless steel mold is not easy to rust, and customer maintenance is convenient. Because the ultrathin box generally has a thin profit, if it rusts, it means that it needs to be re-polished, which will increase the gram weight of the product and eat the profit. Moreover, the polishing performance of S136 is better, and the transparency of transparent products is better. Finally, S136 is a hardened steel material, not easy to deformation, generally ultra-thin box customers are high-speed and high-pressure production, if the steel hardness is not enough, the mold is easy to deformation and eccentricity.

The small knowledge about the selection of steel material for thin-wall lunch box mould is introduced here. If you need high-quality disposable packaging box mold, welcome to consult GEENO MOULD , we will be generous to introduce and recommend the most suitable program for you, tailor the best program for you, so that you get the maximum value of the mold and equipment.

Want to learn more about thin-walled lunch box molds? GEENO will tell you seriously and responsibly!

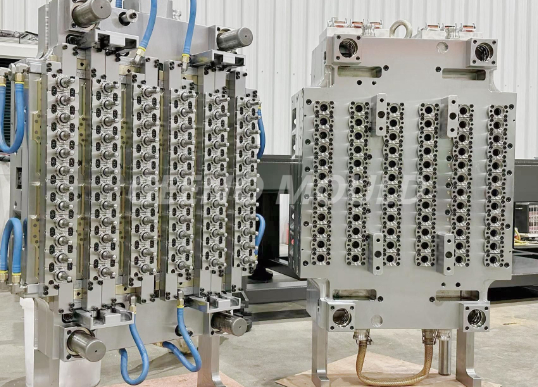

72 Cavities PET Preform Mould | Preform Mould Maker In China - Geeno Mould

PET Preform mould manufacturer - GEENO MOULD,which is own more than 20 years experienced in various kinds of PET Preform Moulds R&D and making. GEENO MOULD is a professional PET Preform Mold Manufacturer in China ,we provide one-stop service from bottle preform mold design to preform mold production to provide after-sales service.

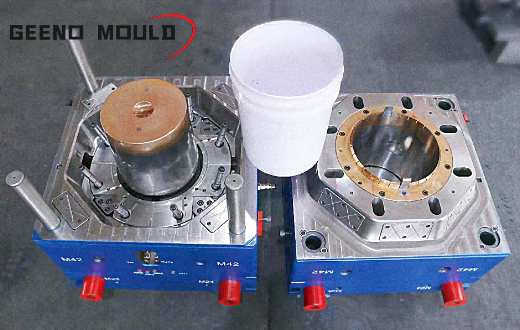

Bucket Mold | 20L Paint Bukcet Mould-GEENO MOULD

GEENO MOULD provide High-quality Bucket Mould for you with a new design structure. 20 L/ 18L/15L/12L/10L/8L/5L/3L/1L Bucket moulds .. We provide you with not only a mold, but also a one-stop complete design and solution. The team will carry out one-to-one design and optimization according to your product, fully considering the optimization and solution of the circulating water, and shorten the molding cycle as much as possible.

Innovative Thin-Walled Container Mold

In a fast-paced life, we need a convenient, reliable, and multifunctional container to meet our various needs. Gino's innovative thin-walled container mold is designed for this purpose. It is not only lightweight and portable, but also durable and reliable, allowing you to enjoy a convenient user experience anytime, anywhere. Whether storing food, decorating items, or serving as a small plant pot, innovative thin-walled container molds can meet your needs.

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message