Describe the structure of the plastic injection mould - GEENO MOULD

2023-02-13 | NEWS

Describe the structure of the plastic injection mould - GEENO MOULD

Plastic injection mold is widely used in our daily life, we are seeing plastic products, such as:

daily necessities, automotive parts, packaging bottles, PVC pipe etc...

All are produced by injection mold and injection machine.

How about we discuss the structure of injection mold?

GEENO Mould Co., Ltd. is located in Huangyan, the famous hometown of mould in China.

As an experienced plastic mould manufacturer, we are here to share with you what parts are the structure of plastic mould composed of?

- The mold setting part is also called the cavity of the mould.

The fixed part of the fixed plastic mold is fixed on the table surface of the hydraulic press or the fixed template of the injection machine

- The moving mold part, also known as the mold core. It is fixed on the movable table surface of the

hydraulic press or the movable template of the injection machine, and the mold is closed and opened through the

movement of the machine tool to press and take out the plastic parts.

- Forming part. It is a part of the geometric shape of plastic parts, forming the shape of plastic parts called cavity, hole or groove called core.

- Gating system. It ensures that the molten plastic can fill the cavity smoothly and smoothly to make the required plastic parts.

- Side core-pulling mechanism. When there is a hole in the side wall of the plastic part, it is necessary to use this mechanism to extract the core.

- Heating and cooling devices. It keeps the mold at a certain temperature to ensure the smooth forming of plastic parts.

- Exhaust and overflow device. Generally, shallow slots are opened on the parting surface

to exclude the gas in the cavity and overflow excess plastic to ensure the quality of plastic parts.

- Discharge device. It is composed of pushing plate, pushing rod, fixed plate, etc. The unloading device of fixed plastic mold

is placed on the moving mold part, so as to remove the plastic parts after opening the mold.

A good plastic injection mold not only needs the above basic mold structure, but also needs professional design,

project and inspection team. Time to verify the design feasibility of the mold, mold processing accuracy is accurate?

Is the mold easy to operate and most efficient?

If you are also looking for high quality, professional plastic mold suppliers, welcome to contact GEENO mold,

we will provide you with the perfect one-stop solution.

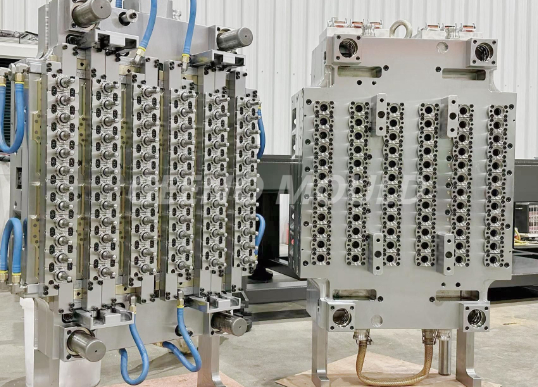

72 Cavities PET Preform Mould | Preform Mould Maker In China - Geeno Mould

PET Preform mould manufacturer - GEENO MOULD,which is own more than 20 years experienced in various kinds of PET Preform Moulds R&D and making. GEENO MOULD is a professional PET Preform Mold Manufacturer in China ,we provide one-stop service from bottle preform mold design to preform mold production to provide after-sales service.

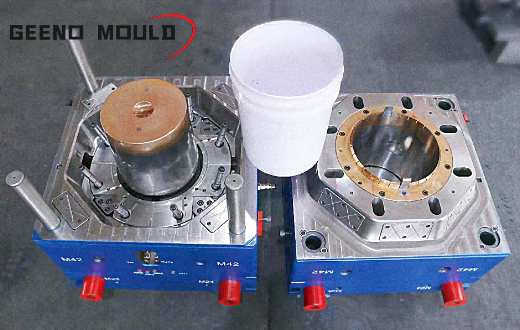

Bucket Mold | 20L Paint Bukcet Mould-GEENO MOULD

GEENO MOULD provide High-quality Bucket Mould for you with a new design structure. 20 L/ 18L/15L/12L/10L/8L/5L/3L/1L Bucket moulds .. We provide you with not only a mold, but also a one-stop complete design and solution. The team will carry out one-to-one design and optimization according to your product, fully considering the optimization and solution of the circulating water, and shorten the molding cycle as much as possible.

Innovative Thin-Walled Container Mold

In a fast-paced life, we need a convenient, reliable, and multifunctional container to meet our various needs. Gino's innovative thin-walled container mold is designed for this purpose. It is not only lightweight and portable, but also durable and reliable, allowing you to enjoy a convenient user experience anytime, anywhere. Whether storing food, decorating items, or serving as a small plant pot, innovative thin-walled container molds can meet your needs.

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message