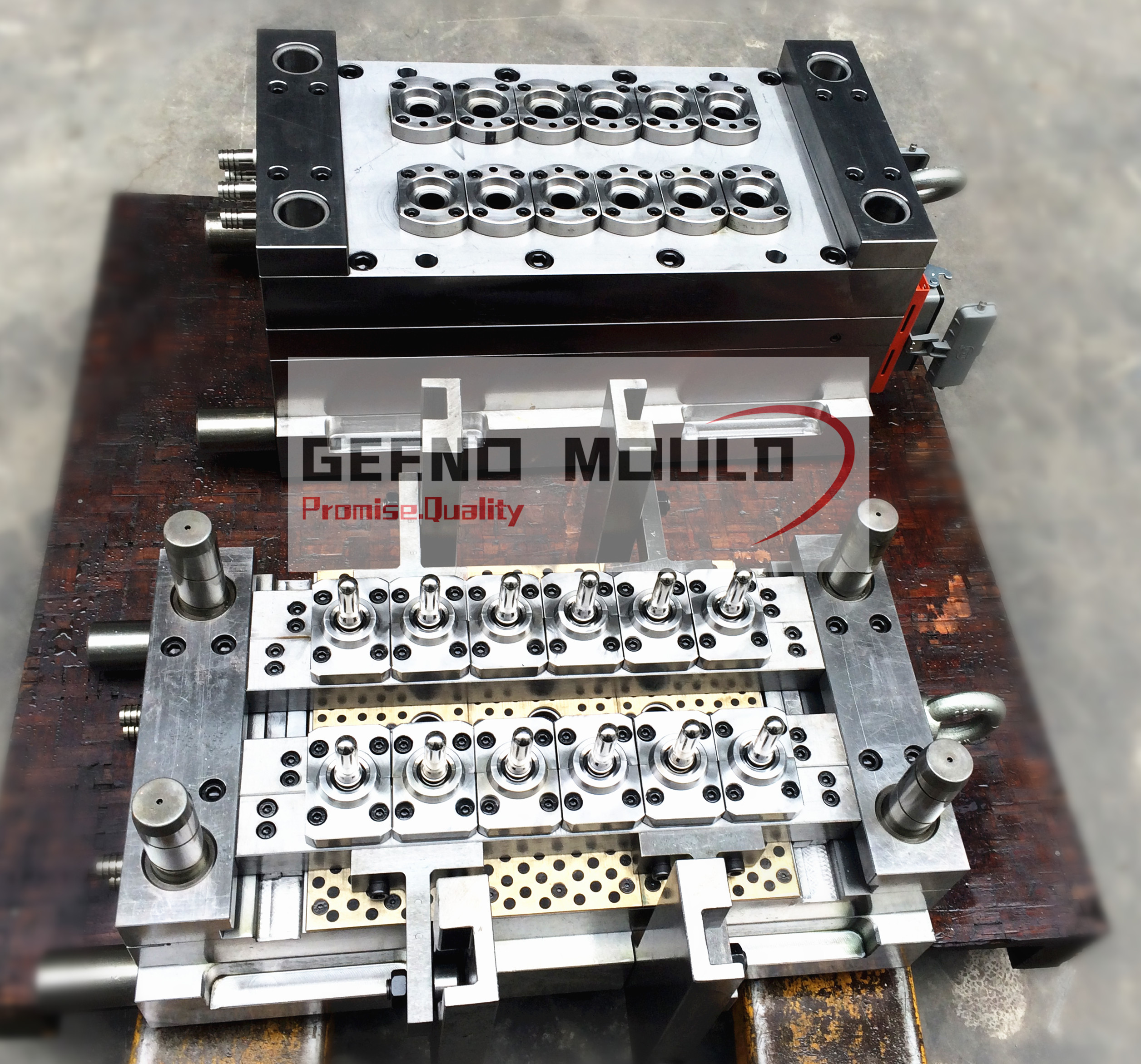

How To Make A Good PET Preform Mold ?GEENO MOULD

2023-09-11 | NEWS

The current application of PET Preform molds is relatively common. In our daily life, they are commonly used in various packaging industries such as edible oil, beverages, candy, medicine, etc.

They have the characteristics of energy conservation, high efficiency, and long service life.

In addition, the PET Preform molds adopt the international advanced second-level double taper positioning technology, with each cavity independently self-locking to ensure the concentricity of the mold.

The excellent cooling system achieves high efficiency of constant temperature water cooling, and there is no shear gate, reducing labor intensity for workers.

The mold has a lifespan of at least 3 million mold cycles

Process of PET Preform mold:

1. Sensitivity to oxidation and decarbonization. When heated at high temperatures, it has good antioxidant capacity and is not sensitive to the heating medium.

2. Hardening, with uniform surface hardness after quenching.

3. Hardenability. After quenching, a deeper hardening layer can be obtained, and quenching can be achieved using a mild quenching medium.

4. Conventional quenching has small volume changes, low tendency for abnormal deformation, low cracking sensitivity, and is not sensitive to quenching temperature.

5. Good grindability, low relative loss of grinding wheel, less prone to abrasion and grinding cracks.

Factors affecting the formation of PET Preform mold:

Product plastic forming stage. The common phenomenon is the deformation of the mold embryo due to high-pressure blowing,

and the contact deformation between the mold embryo and the mold cavity.

The factors that affect this situation include the shrinkage rate of the material; Blowing pressure and time;

The material and structure of the mold; the Mold exhaust system and the mold cooling system.

Blanking stage. The common phenomena are the expansion of the embryo from the mold and the elongation of the embryo.

The factors that affect these two phenomena include the diameter of the mold head and the wall thickness control system of the blow molding machine.

The control system includes an axial wall thickness control system and a circumferential wall thickness control system, which are used to adjust the gap between the mold lip and the mold core.

What should be done for the repair and maintenance of PET Preform molds?

1. Regular maintenance: Inspect the entire mold on time, especially for fast wear and important key components.

2. Mechanical lubrication: Timely replenish lubricating oil for mechanical components that require lubrication,

such as robotic arms, reducers, host bearings, movable guide rails, mold guide pillars, guide sleeves, and internal and external bayonets.

3. Mold maintenance: The cooling water channel of the PET Preform mold needs to be maintained with softened water,

and scaling should be cleaned in a timely manner and inspected monthly;

Regularly use professional cleaning agents inside the mold cavity and conduct monthly inspections of the mold exhaust slots to prevent clogging of the exhaust holes.

Welcome to contact us, GEENO Molding Co., Ltd., to learn more about injection mold solutions for Multi-cavity PET Preform mold !

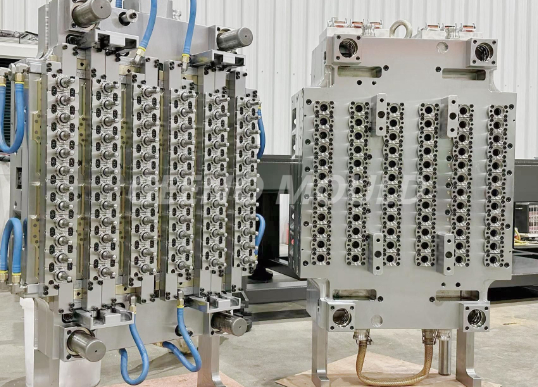

72 Cavities PET Preform Mould | Preform Mould Maker In China - Geeno Mould

PET Preform mould manufacturer - GEENO MOULD,which is own more than 20 years experienced in various kinds of PET Preform Moulds R&D and making. GEENO MOULD is a professional PET Preform Mold Manufacturer in China ,we provide one-stop service from bottle preform mold design to preform mold production to provide after-sales service.

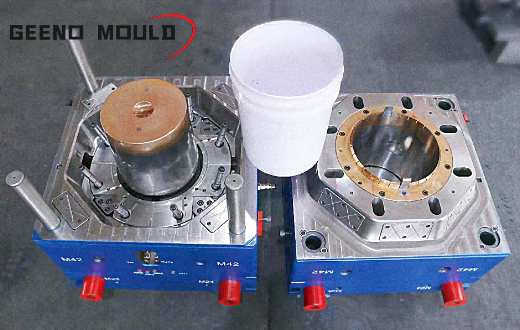

Bucket Mold | 20L Paint Bukcet Mould-GEENO MOULD

GEENO MOULD provide High-quality Bucket Mould for you with a new design structure. 20 L/ 18L/15L/12L/10L/8L/5L/3L/1L Bucket moulds .. We provide you with not only a mold, but also a one-stop complete design and solution. The team will carry out one-to-one design and optimization according to your product, fully considering the optimization and solution of the circulating water, and shorten the molding cycle as much as possible.

Innovative Thin-Walled Container Mold

In a fast-paced life, we need a convenient, reliable, and multifunctional container to meet our various needs. Gino's innovative thin-walled container mold is designed for this purpose. It is not only lightweight and portable, but also durable and reliable, allowing you to enjoy a convenient user experience anytime, anywhere. Whether storing food, decorating items, or serving as a small plant pot, innovative thin-walled container molds can meet your needs.

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message