Application Of Plastic Turnover Boxes

2023-09-15 | NEWS

Application of plastic turnover boxes

In today's increasingly valued logistics management by enterprises,

plastic turnover boxes are essential for achieving the universality and integration of logistics containers,

as well as modern logistics management for production and distribution enterprises.

GEENO Moulding Co., Ltd., have over 15 years of experience in the mold manufacturing industry,

erving various countries around the world and providing customers with high-quality services and experiences.

The main application scope of plastic turnover boxes is in machinery, automobiles, household appliances, light industry,

electronics industry, oil pollution, cleaning, and parts. Plastic turnover boxes are suitable for transportation, distribution,

storage, distribution and processing in factory logistics due to their convenient turnover, neat stacking,convenient management,

reasonable design, and excellent quality. They can cooperate with multiple logistics containers and platform equipment,

and are used in various warehouses, production sites, and other occasions.

The characteristics of plastic turnover boxes:

1. Stable performance:

The plastic turnover box can be waterproof, moisture-proof, anti-corrosion,insect proof, and fumigant free.

Compared with cardboard and wooden boards, it has obvious advantages.

2. Material saving and quality assurance:

The plastic turnover box has excellent mechanical properties, uses less plastic hollow boards, has low costs, and is lightweight.

3. Insulation and sound insulation:

The hollow structure of plastic turnover boxes significantly reduces their heat

and sound transfer effects compared to solid panels, providing excellent insulation and sound insulation effects.

4. Beautiful and practical:

The special molding process of plastic turnover boxes can achieve any color through color mixing of color masterbatches.

And the surface is smooth and easy to print.

How to maintain plastic turnover boxes:

1. Regular wiping

During use, there may be some dirt and plastic residue left on the surface of the box.

We should regularly wipe it with soft cloth and avoid using hard objects or abrasives.

2. Avoiding impact

Plastic molds are prone to cracks and notches when subjected to external forces.

Therefore, it is important to avoid being hit by hard objects during use.

3. Pay attention to the ambient temperature

During the storage process of plastic molds, attention should be paid to the temperature of the environment,

as it is prone to performance changes in high temperature environments, thereby shortening the lifespan of the mold.

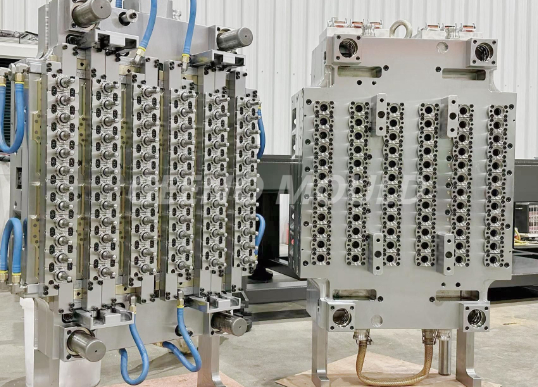

72 Cavities PET Preform Mould | Preform Mould Maker In China - Geeno Mould

PET Preform mould manufacturer - GEENO MOULD,which is own more than 20 years experienced in various kinds of PET Preform Moulds R&D and making. GEENO MOULD is a professional PET Preform Mold Manufacturer in China ,we provide one-stop service from bottle preform mold design to preform mold production to provide after-sales service.

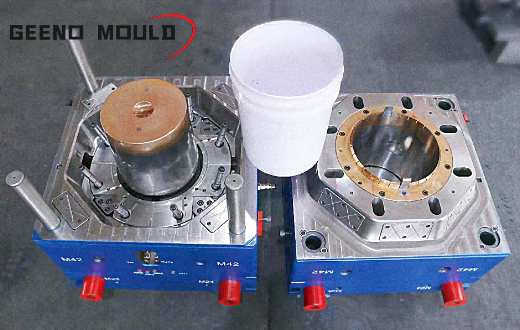

Bucket Mold | 20L Paint Bukcet Mould-GEENO MOULD

GEENO MOULD provide High-quality Bucket Mould for you with a new design structure. 20 L/ 18L/15L/12L/10L/8L/5L/3L/1L Bucket moulds .. We provide you with not only a mold, but also a one-stop complete design and solution. The team will carry out one-to-one design and optimization according to your product, fully considering the optimization and solution of the circulating water, and shorten the molding cycle as much as possible.

Innovative Thin-Walled Container Mold

In a fast-paced life, we need a convenient, reliable, and multifunctional container to meet our various needs. Gino's innovative thin-walled container mold is designed for this purpose. It is not only lightweight and portable, but also durable and reliable, allowing you to enjoy a convenient user experience anytime, anywhere. Whether storing food, decorating items, or serving as a small plant pot, innovative thin-walled container molds can meet your needs.

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message