What does the mold check before put into machine

2022-11-21 | NEWS

Before reading this article, it is clear that the following problems will not occur if we cooperate with Geeno mould, because Geeno will fully consider these problems in product design and mold design.

1. Length of mold

Only when the length of the mold is less than the interval of the Corinth column can the mold be put in smoothly. If the length of the mold is greater than the interval of the Corinth column, the width and height of the mold are less than the interval of the machine, the mold can be turned 90 degrees, put in and then turn back, but we do not agree with this method.

2.Positioning ring

The outer diameter of the positioning ring is consistent with the positioning hole of the machine.

Welcome to contact us for more information about Injection Mould Solutions!

3. Maximum mould opening distance

When the mold is fully opened, the opening distance is less than the maximum opening distance of the machine can be produced. Some molds are installed, and this problem is found, the shorter outer pull rod will be replaced. If the product can be successfully demoulded, the product can also be successfully demoulded, but some products can not be successfully demoulded for shorter outer pull rod, or there are bad problems such as bumps and injuries, so it can not be produced.

4. Confirmation of maximum and minimum mould thickness

Because the hydraulic press is a direct press, its maximum mould thickness is equivalent to the maximum mould opening distance, the maximum mould thickness is generally not a problem.

Motor and other non-direct pressure type, mold height should be less than the maximum thickness of the machine to install the mold.

The minimum mould thickness is the same, the mold height must be greater than the minimum mould thickness of the machine to install the mold.

5. Maximum mould opening stroke

The maximum mould opening stroke of direct press molding machine is the maximum mould opening distance minus the mould height, so it is a variable value, with the mould height change and different.

The maximum opening stroke of the bending elbow molding machine is a fixed value, which varies according to the model of the molding machine.

6. Ejection device

The outside diameter of the ejector rod should be less than the inside diameter of the hole of the ejector rod of the mould.

The effective ejection length, that is, the length from the plane of the plate to the full ejection, is greater than the ejection distance when the product is smoothly demoulded. The number and position of the ejector rod should be consistent with the mold.

7. Sprue

The mold nozzle R should be larger than the machine nozzle r. Generally, it is better to be about 2mm larger. The aperture of the mold nozzle is slightly larger than that of the machine nozzle, so that the main channel can be demoulded smoothly.

8, Metering Stroke

The machine has a certain metering stroke, according to the weight or volume of the product to calculate the required metering stroke, is generally controlled in more than 20%, below 70% is better, of course, smaller and larger can also be produced, but whether it is on the product or the machine has a negative impact.

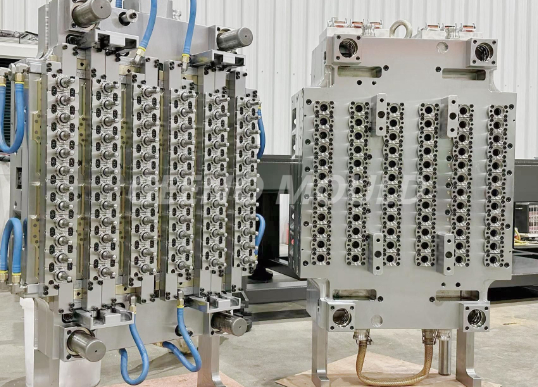

72 Cavities PET Preform Mould | Preform Mould Maker In China - Geeno Mould

PET Preform mould manufacturer - GEENO MOULD,which is own more than 20 years experienced in various kinds of PET Preform Moulds R&D and making. GEENO MOULD is a professional PET Preform Mold Manufacturer in China ,we provide one-stop service from bottle preform mold design to preform mold production to provide after-sales service.

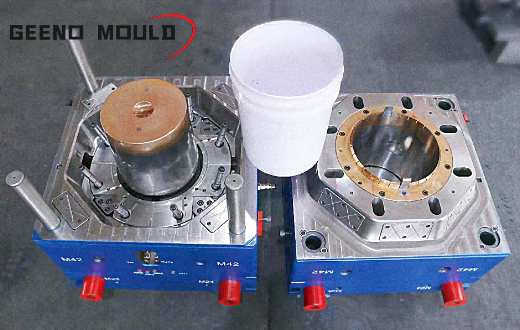

Bucket Mold | 20L Paint Bukcet Mould-GEENO MOULD

GEENO MOULD provide High-quality Bucket Mould for you with a new design structure. 20 L/ 18L/15L/12L/10L/8L/5L/3L/1L Bucket moulds .. We provide you with not only a mold, but also a one-stop complete design and solution. The team will carry out one-to-one design and optimization according to your product, fully considering the optimization and solution of the circulating water, and shorten the molding cycle as much as possible.

Innovative Thin-Walled Container Mold

In a fast-paced life, we need a convenient, reliable, and multifunctional container to meet our various needs. Gino's innovative thin-walled container mold is designed for this purpose. It is not only lightweight and portable, but also durable and reliable, allowing you to enjoy a convenient user experience anytime, anywhere. Whether storing food, decorating items, or serving as a small plant pot, innovative thin-walled container molds can meet your needs.

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message