GEENO TECH GROUP

GEENO Team is one of the member branch of GEENO TECH Group. Which Founded in 1998. Through nearly 30 years development Sunbun Group now have Wenzhou, Hangzhou, Shanghai , Xuzhou ,Quzhou 7 Production Base. Focus on supplying the most suitable and the best plastic injection molding solution for customers all over the world . Honesty , Quality , Sincerely Responsibly .

Since

Middle and senior technical

R&D department members

Over 1500.00 square meters.

Equipments

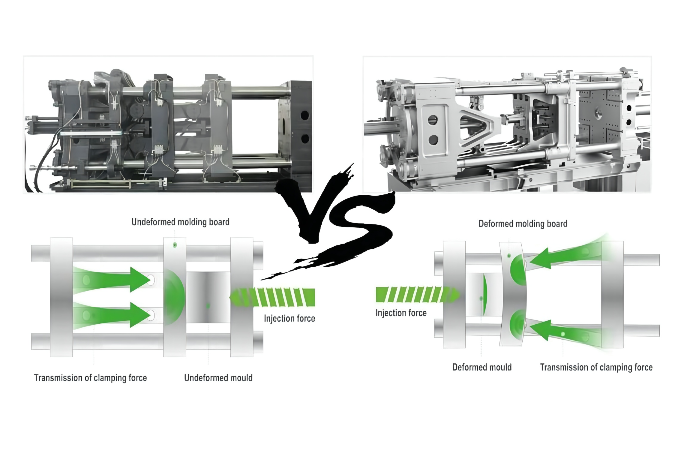

SK Injection Molding Machine Advantage

* Mechanical Direct Clamping Structure - New design for SK Series Injection Molding Machine with Servo Energy Saving . Offering you with various kinds of plastic injection molding machine types . Such as : - SK Series fast speed injection molding machine with servo motor ; - PET Customized Servo injection moulding machine series ; - PVC Customized Servo injection molding machine series ; - Double-color Customized Servo injection moulding machine series; - Two-platen injection molding machine series ....

Why Choose Our Plastic Injection Molding Machine ? ? ?

* LARGE

Long stroke and mouldthicknessResilient mould thickness and long displacement stroke.

* MORE STABLE

Reinforced molding board, thicker pull rod, high-rigidity frame,with more stable operation state and longer service life.

* MORE ECONOMICAL

Reasonable oil circuit design, which is more energy-saving, improves the operating speed and can save 2%-6%raw materials from 90% products for the customers.

Plastic Injection Molding Machine Series

- SK New Model Injection Moulding Machine

* Plastic Injection Machine model cover from 50T to 3300T with Servo motor . * Resilient mould thickness and longdisplacement stroke * Reasonable oil circuit design, which is more energy-saving, improves the operating speed and can save 2%-6%raw materials from 90% products for the customers. * Reinforced molding board, thicker pull rod, high-rigidity frame,with more stable operation state and longer service life.

- Medical Customized Injection Molding Machine

* Plastic Injection Molding Machine model cover from 50T to 650T with Servo motor . * High Precision Machining for Injection molding machine * Reasonable oil circuit design, which is more energy-saving, improves the operating speed and can save 2%-6%raw materials from 90% products for the customers. * High Safety with high speed for high precision medical parts products manufacturing.

- SK Large Model Injection Molding Machine

* Our Plastic Injection Molding Machine model cover from 50T to 3300T with Servo motor . * 100% clamping use ratio, 10%-20% higher than thatof traditional structures; * Less fins on the finished products; * 2%-6% raw materials saved from production thanthat of traditional structures; * Opening stroke 10%-20% longer than thatof traditional structures;

- SK PET Injection Moulding Machine

* Injection Molding Machine model cover from 50T to 650T with Servo motor . * Enlarged motor, oil pump, servo motor and servo driver to control the production cycle time for plastic injection machine. * High Precision with special PET screw and barral ,Plastic Injection Machine with PET special screw and enlarged plasticizing motor. * Enlarged plasticizing motor for our Plastic Injection Molding machine bigger torque to meet PET material special characteristic;

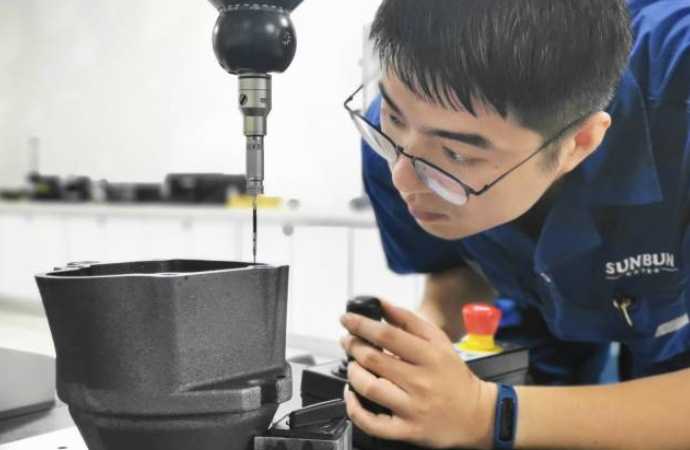

Machine Production & QC Team

To make a high quality Injection Molding Machine and ensure our plastic injection machine precision for all of our customers , It's very important to invest High-precision inspection and metal material analysis equipments: CMM, spectral analysis, roundness instrument imported from Switzerland, the United Kingdom, and Japan.

Plastic Injection Molding Machine Gallery

JOIN US !!!

Join us and be one of us ! We will give you our utmost support for Turnkey Solution of Plastic Injection Molding all over the world ! Now we have established offices in many countries. Would you like to join us?

File Download

SK Series Machine Catalog 2021

Download

2021-01-21Our Partners

Thanks for your trust, GEENO & SUNBUN team will always do our best to give the most suitable solution of plastic injection molding for you !

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message